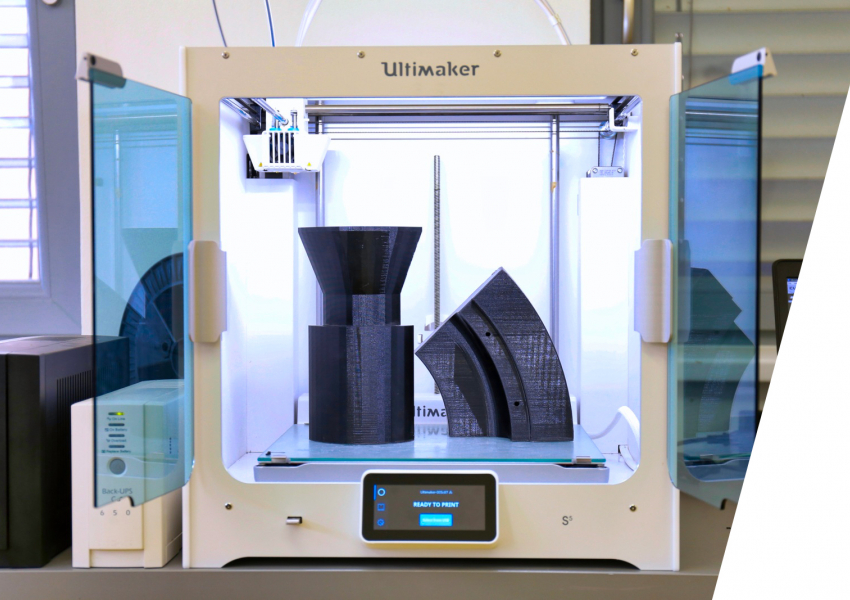

The company “Průmyslová keramika” is active in the production and sales of various types of non-shaped refractory masses and parts made from such masses. Practically every job order needs to develop a unique customized solution to meet highly individual requirements of our customers. Specifically, an additive production technology has proved to be an ideal solution to production of forms for individual parts.

Almost always, the form to produce parts consists of an external casing, defining overall shape, typically made from steel, and cores, detailing important functional details – grooves, holes, waves etc. Frequently, core shapes are incredibly complex; however, they must be designed and produced precisely as requested by the individual customer.